Failure criteria serve as essential assessment tools used to determine the load-bearing capacity of materials. They have been extensively employed in engineering design across various domains, encompassing products and structures such as machinery, vehicles, and buildings. Apart from contributing to the safety factor of the design, failure criteria also play a crucial role in maximizing material utilization, leading to cost savings in material expenses.

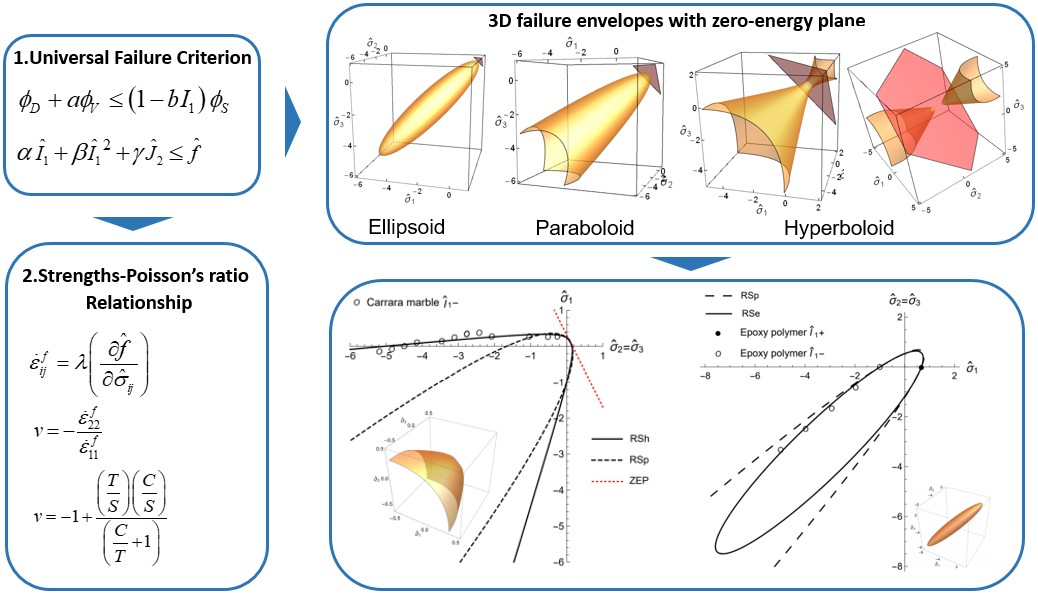

Driven by this concern, Dr. Sontipee and his master’s student, Pijak Tiraviriyaporn, embarked on a pioneering endeavor to establish an energy-based universal failure criterion and strengths-Poisson’s ratio relationship for isotropic materials. The team hypothesized that a universal failure criterion could be formulated to cover all types of materials. In their investigation, existing failure criteria were thoroughly examined before proposing a universal criterion for isotropic materials.

In contrast to previously developed failure criteria that require a broad array of parameters, this universal failure criterion solely relies on two load-bearing capabilities of the material: tensile and compressive strengths. This universal criterion achieves over 90% accuracy across a diverse range of isotropic materials, spanning from ductile to brittle materials.

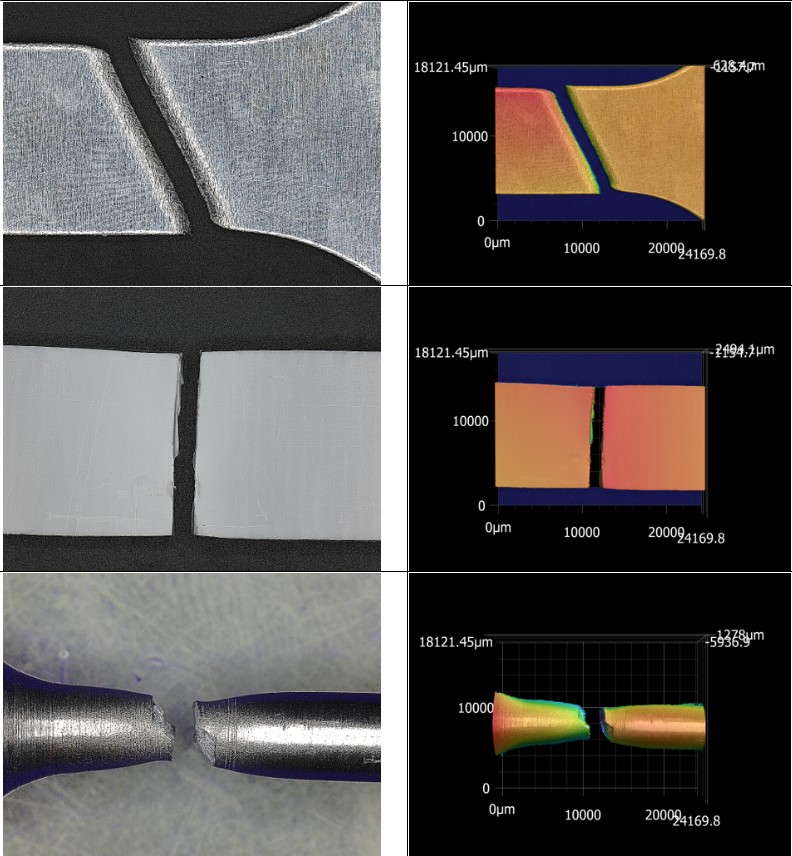

Pijak highlights that the knowledge acquired from this study can be effectively applied to conduct post-accident analyses of vehicle components and wreckage. This analysis helps determine the impact of a crash and identify the root cause of the accident. Looking ahead, Dr. Sontipee suggests that this research finding can also contribute to the determination of load-bearing capability of composite materials. Furthermore, it has the potential to be integrated into engineering design software, streamlining its usability.

“While the immediate economic impact of this study may not be apparent, it serves as a pivotal cornerstone for research and development. Advancements in failure theory have the potential to greatly accelerate materials research and innovation, leading to the creation of novel materials with enhanced properties and functionalities for a wide range of industrial applications. For instance, it can enable the development of lighter and stronger materials for the construction industry,” concludes Dr. Sontipee.

This study has been reported in an article titled “Energy-based universal failure criterion and strength-Poisson’s ratio relationship for isotropic materials” published in the International Journal of Mechanical Sciences (IJMS) in September 2022.