Flooding stands as one of the most prevalent natural disasters in Thailand, presenting a significant challenge to the well-being, safety, and health of countless individuals. Those residing alongside flooded roads and streets, including residents, homeowners, and shopkeepers, are faced with not only the inundating waters but also the waves generated by passing vehicles, which pose risks to their safety and cause damage to their properties. In response to this predicament, a team of engineering students from KMUTT has developed a solution known as the “Floating Wave Barrier,” designed to reduce the force of vehicle-induced waves on the flooded road. The team comprises Wachirawit Rangdang, a fourth-year student from the Department of Mechanical Engineering, as well as Papakkorn Sukphen and Rungaroon Khunsamitpanya,both fourth-year students from the Department of Electrical Engineering.

Wachirawit states that the objective of the project was to create a barrier that surpasses the capabilities of a conventional traffic barrier in mitigating the impact of waves generated by vehicles. Drawing inspiration from wave barriers deployed along shorelines to shield beaches from the force of waves, the team devised their design.

Nevertheless, unlike conventional wave barriers, which are typically tailored to confront predictable waves of specific sizes and directions, the barrier created by this team must be able to endure the impact of waves generated by vehicles of varying sizes and velocities. It also needed to function effectively across diverse floodwater levels.

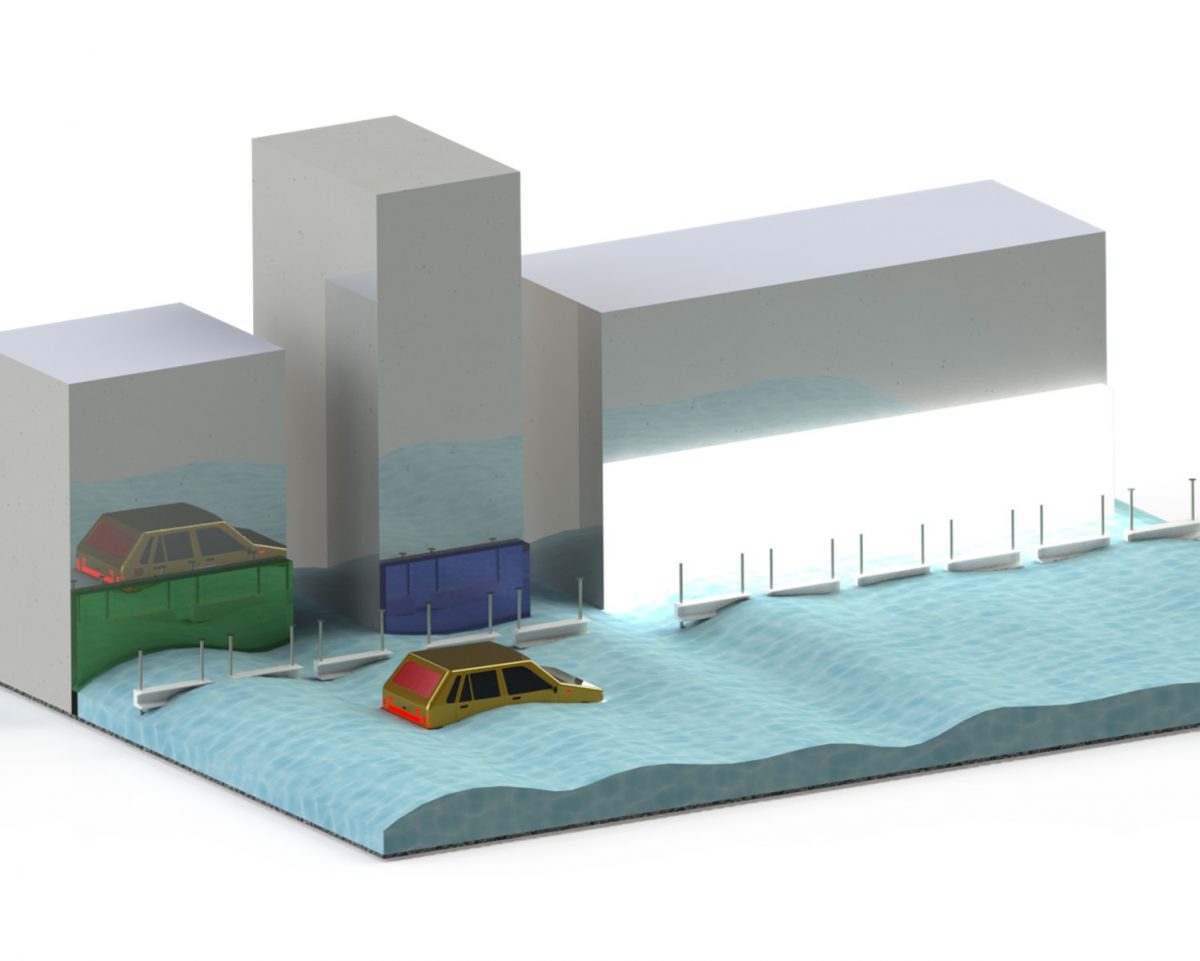

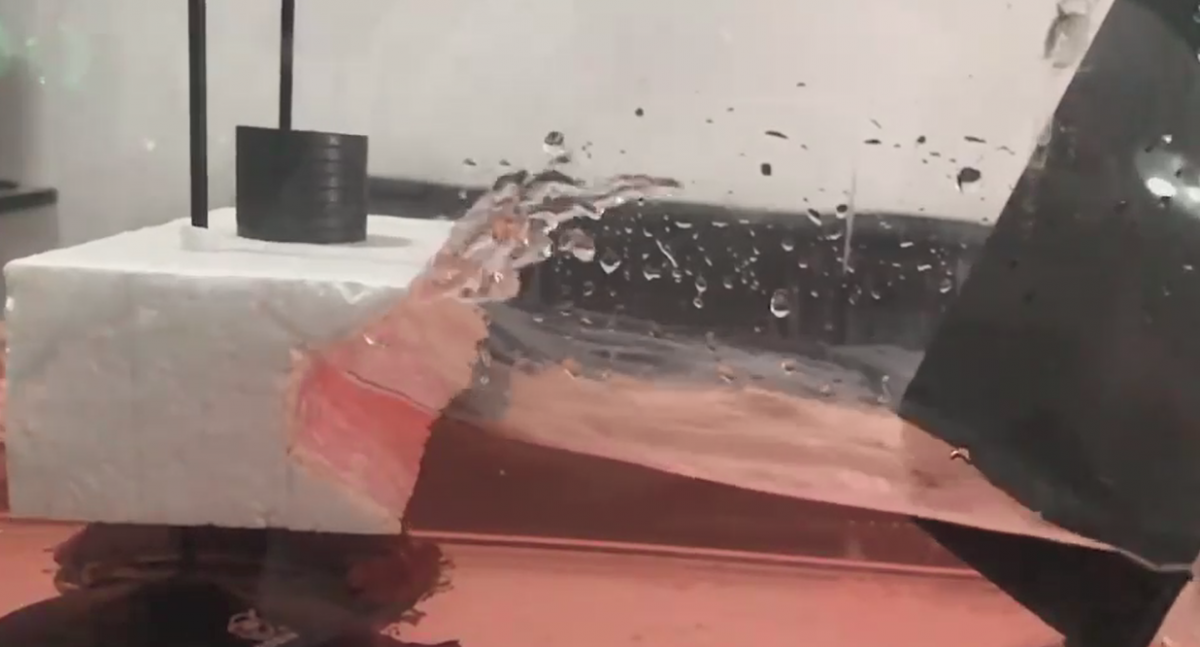

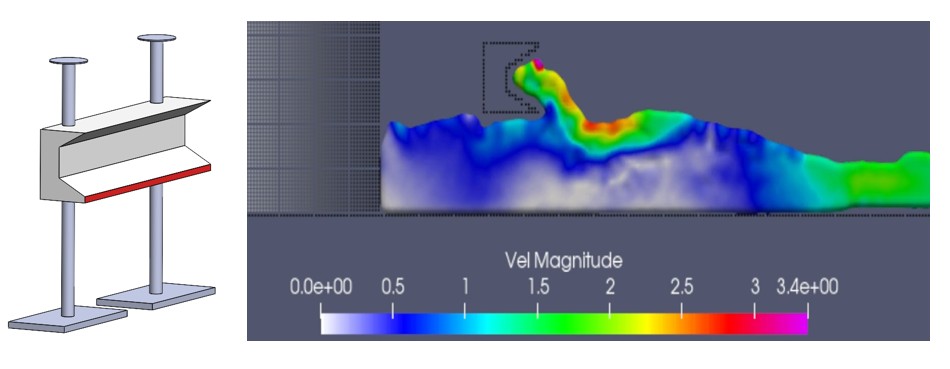

Papakkorn explains the distinctive design of their wave barrier. Given the fluctuating nature of flood levels, constructing a fixed-height, towering barrier would not only prove costly but also pose challenges in terms of transportation. To create a lighter and height-adjustable structure, the team devised a system consisting of two components: a lightweight floating barrier and a base equipped with two galvanized poles for barrier mounting. The barrier’s impact-receiving side was fashioned in a curved shape resembling the letter C, which served to reduce and redirect the wave impact. The design also enabled a loose fit between the floating barrier and the poles, facilitating vertical and horizontal movement of the barrier in response to water levels and generating a counteracting wave to neutralize the waves produced by vehicles. In addition to reducing wave force, the floating wave barrier can reflect and dissipate the impact of incoming waves. Based on computational fluid dynamics analysis and a 1:10 scale model, the proposed structure demonstrated the potential to reduce wave force by up to 42.7%.

According to Rungaroon, their device offers several advantages over conventional traffic barriers. It is smaller and lighter, with a floating wave barrier weighing 15 kg compared to the 22 kg of a traditional traffic barrier, allowing easier transportation and storage. Additionally, the barrier’s adjustable height spans from 20 cm. to 1 m., enabling it to adapt to various flood levels. Pedestrians can easily cross the floating barrier when it is set to its low height, whereas traditional barriers with a fixed height of 1 meter could not be crossed.

Wachirawit further highlights that due to the similarity of wave patterns generated by various vehicles, this device can also be deployed along canals to alleviate wave forces induced by passing boats.

Recognized for their innovative, validated, and practical design, the team was awarded the first runner-up prize in the Ford+ Innovator Scholarship 2021 competition. They attribute their success to the guidance of Dr. KamthonSeptham, a lecturer from the Department of Mechanical Engineering at KMUTT, who advised them to employ tools such as simulation and scale model testing as substitutes for physically constructing prototypes, which posed challenges due to the COVID-19 pandemic and time constraints. The team also expresses gratitude to the Faculty of Engineering at KMUTT for furnishing them with various tools and resources, including computer workstations, to facilitate their computational analyses.