Accurate estrus detection is paramount for the success of dairy operations since cows must become pregnant and give birth to produce milk. Survey data indicates that dairy farms in Thailand have achieved a mere 60% insemination rate, primarily attributed to inaccurate estrus detection. Failed insemination results in an additional 21-day wait for the next estrus cycle, significantly diminishing the economic profitability of dairy operations.

A team of KMUTT students has developed an IoT-based estrus detection system known as KomilO. The team comprises both undergraduate and graduate students from the School of Information Technology. The team members include Minthorn Phunthawornwong, Treetep Seangow, Kitsakorn Lasree, Kanawat Phuengphadung, Thitikorn Wangsaen and Worravaran Treetippayanan. Guiding the team as their advisor is Dr. Rardchawadee Silapunt, an associate professor from the Department of Electronic and Telecommunication Engineering.

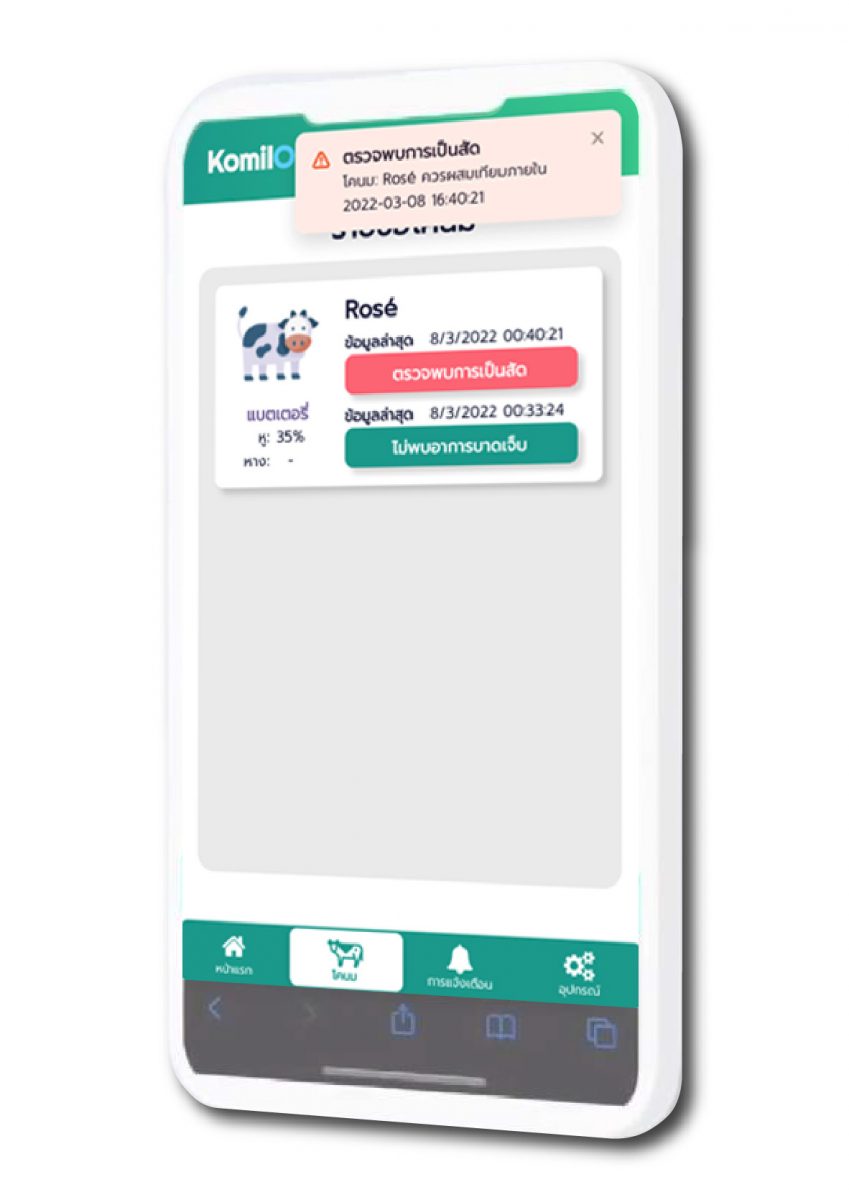

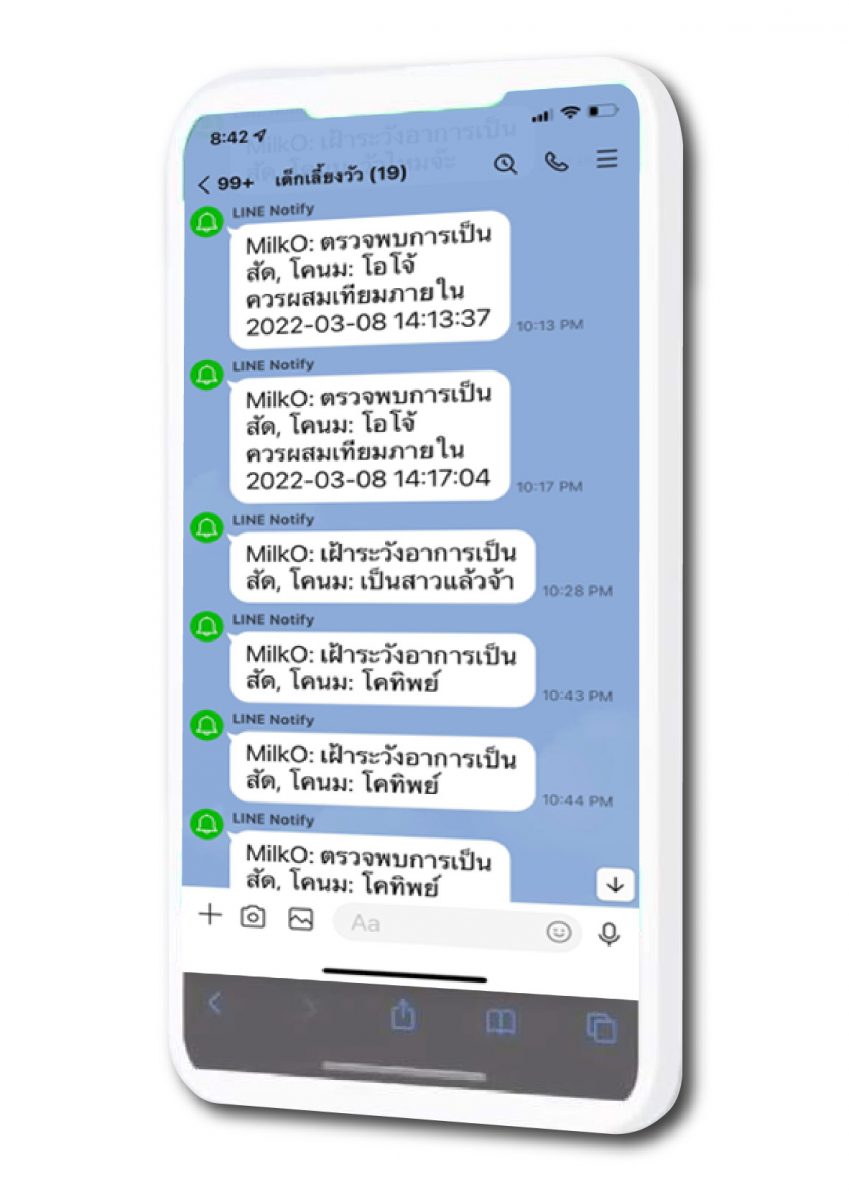

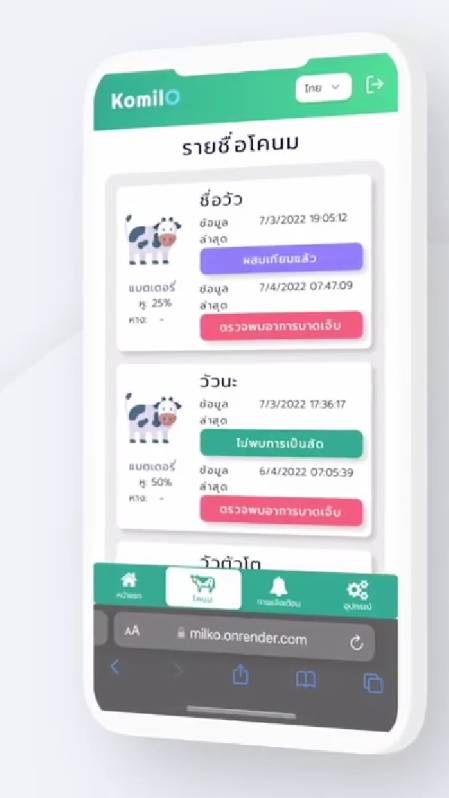

KomilO used two sensors, one affixed to the cow’s ear and the other to its tail. The ear-tag sensor tracks the cow’s movements, including walking, eating, standing, and sleeping, which are utilized in machine learning algorithms to predict the estrus cycle. On the other hand, the tail-attached sensor detects mounting behavior, an indication that the cow is in heat. Both sets of data are transmitted via a wireless communication network to the server for processing and analysis. The sensors themselves are compact, lightweight, and designed with low-power consumption in mind. The ear-attached sensor can operate for up to 14 days on a single charge, while the tail sensor can function for several months once fully charged.

“Although the development of KomilO was arduous and time-consuming at times, involving both fieldwork and app development, the outcome has proven to be immensely gratifying,” Treetep acknowledges. Collaborating with veterinarians and dairy farmers has provided the team with a truly enriching experience. Similarly, Kitsakorn expresses his pride in the team’s accomplishments and recognizes the significant potential impact the system can have on the dairy industry.

This innovation was conceived with a focus on addressing user pain points. However, further development is needed to enhance the system’s stability and ensure its readiness for commercialization. “Having the capability to manufacture such devices within the country will strengthen our food production system. This innovation is a testament to KMUTT’s promise to deliver affordable solutions to our Thai farmers,” concludes Dr. Rardchawadee.