With the power to turn a design into a tangible 3D object, 3D printing has revolutionized the manufacturing industry and become a valuable tool for enhancing students’ skills in art and science. However, the high cost of 3D printers and the requirement for skilled technicians for operation and maintenance have limited their use to only schools with resources.

To overcome this limitation, the Field Robotics Institute (FIBO) has developed Tele 3D Printing – an innovative telelearning lab and resource sharing system – as part of the Robotics for All project. The aim was to maximize the utilization of 3D printers in academic institutes.

Poonsiri Jailungka, a FIBO researcher responsible for the Tele 3D Printing project, shares the origin of this endeavor. In 2018, the National Science and Technology Development Agency (NSTDA) launched the Fabrication Lab (FabLab) project, aiming to foster creativity and skills in design, research, engineering and innovation by setting up fully equipped fabrication labs in educational institutes nationwide and organizing activities such as training workshops and contests. A total of 450 3D printers were provided to 150 high schools and colleges under FabLab project. To maximize the use of these printers, FIBO initiated the Tele 3D Printing project to enable schools that do not have 3D printers to access these printing facilities within their proximity.

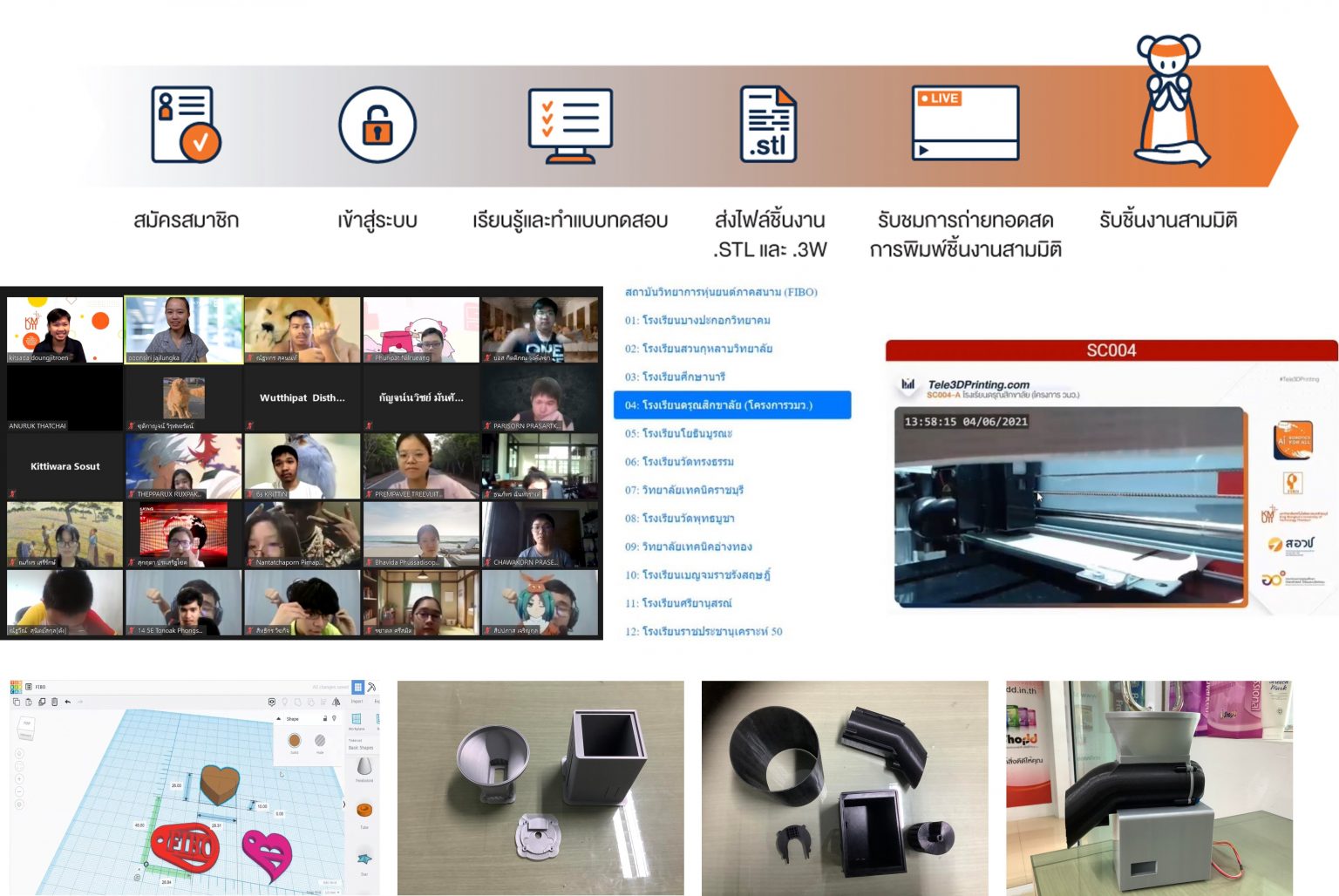

“Our first-year goal was to develop a time-sharing operating system that allows teachers and students from schools with 3D printers to remotely access them, as the printers provided by FabLab did not support wireless networks,” explains Poonsiri. This involved the development of both hardware and software components. A website was created for students to submit files for printing, while teachers could manage the printing schedule. The system was piloted in 20 schools.

“We received feedback from teachers that students were excited to see their designs come to life on the Tele 3D Printing system. Many schools use printers for creating models for science projects, and some teachers have started incorporating 3D printing into other classes, such as art and history. By the end of the first year, each printer had an average usage of 200 to 3,000 users,” adds Poonsiri.

In the second year, the Tele 3D Printing project is set to focus on improving the system’s user-friendliness, organizing design contests, and expanding its coverage to more schools.

This project exemplifies the use of technology to facilitate resource sharing, thereby reducing investment costs and educational disparities. This remote access system also has potential application in “Smart Factory”. Most importantly, the initiative nurtures youth who will grow up with knowledge and understanding of robotics and its invaluable contribution to the manufacturing sector.