Both robots and electric vehicles are transformative technologies and have increasingly played a significant role in our daily lives. An effort has been made by a KMUTT student to apply both technologies to support sea salt harvesting. Norawit Nangsue, a master’s student at the Institute of Field Robotics (FIBO), has developed the “5G Zero Carbon Autonomous Roller for Salt Harvesting.” This innovative robot helps salt farmers save labor costs, reduce fuel consumption, and improve soil compaction in salt evaporation ponds, while saving the planet with its zero-emission engine. The research was supervised by Assoc. Prof. Dr. Djitt Laowattana, Dr. PrakarnkiatYoungkong, and Asst. Prof. Dr. Thavida Maneewarn. The project was funded by the Agricultural Research Development Agency (ARDA), while the roller vehicle for conversion was donated to the project by Norawit’s father.

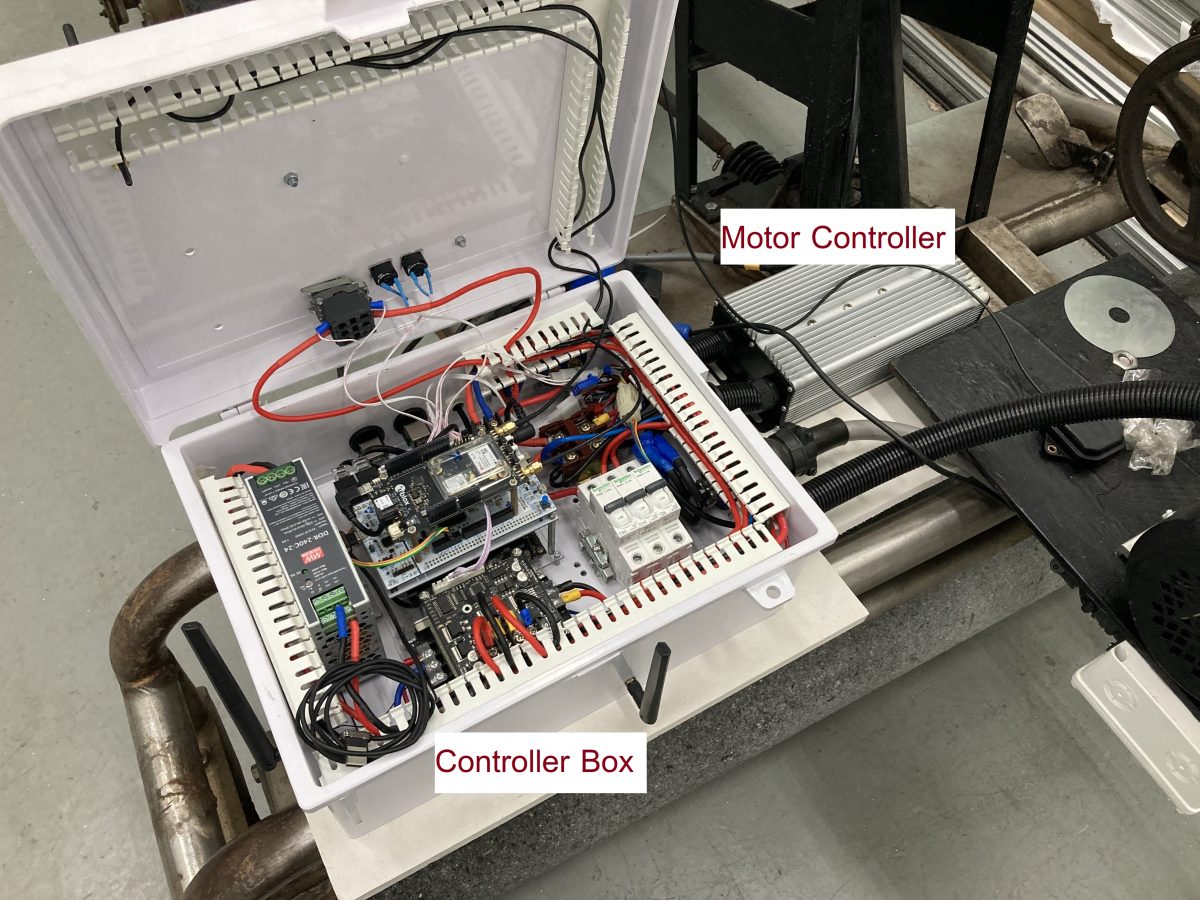

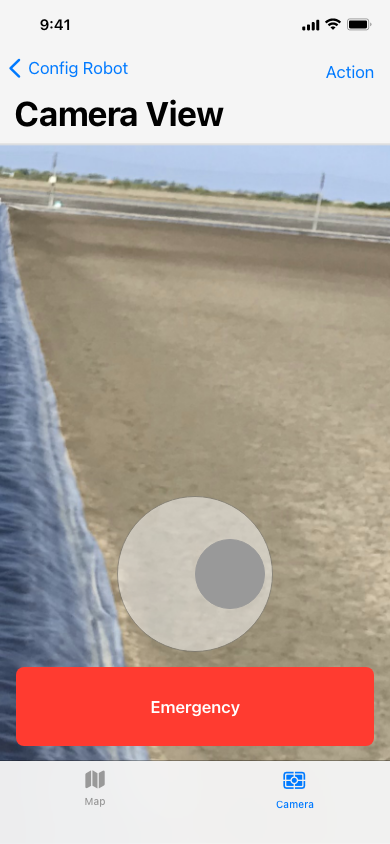

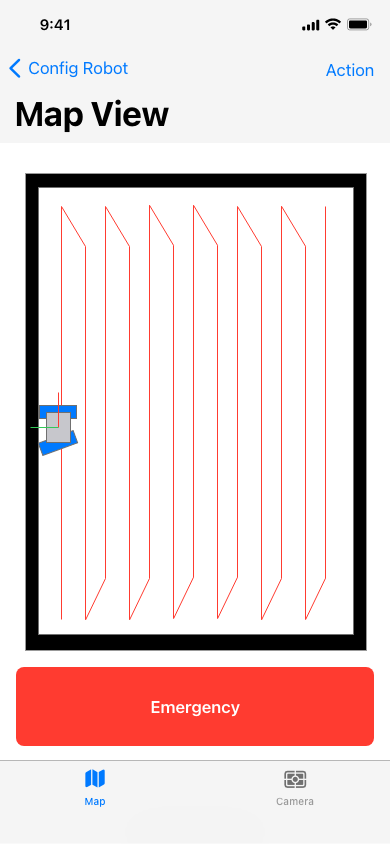

Norawit explains the idea behind his creation. He was inspired by his salt farmer father to create a zero-emissionautonomous roller for salt harvesting by converting a traditional roller vehicle into a self-driving electric roller.The road roller’s internal combustion engine was replaced by a battery-powered electric motor. The self-driving partconsists of two main processes. The path planning process is responsible for determining and creating the vehicle’s path. The subsequent process is the control of the vehicle’s movement along the designated path. Additionally, Real-Time Kinematic Positioning (RTK) technology is employed for accurate positioning, and an Inertial Measurement Unit (IMU) is used to determine the vehicle’s orientation. The vehicle has a width of 1.5 m, weighs approximately 240 kg (160 kg for the vehicle frame and 80 kg for the battery) and has a maximum speed of 1 m/s, depending on the motor used.

Norawit’s family has been running a salt harvesting business in Phetchaburi province since his grandfather. Salt is made by pumping seawater into shallow ponds and waiting for water to evaporate, leaving behind salt crystals on the pond surface. Once the salt crystals reach a thickness of 1-3 centimeters, they can be harvested. After harvesting, the soil surface needs to be rinsed and compacted before letting in a new batch of seawater to minimize soil mixing in with the harvested salt.

Traditionally, soil compaction is done by using a manually roller compactor pulled by 2 to 4 people, or by a road roller which has an internal combustion engine and requires a driver. Typically, it takes about one hour to finish an evaporation pond of the 5,000 sq. m. surface area. This autonomous electric road roller can significantly help our salt farmers save costs. “Besides saving on labor and fuel costs, it produces zero emissions and does not use lubricants and gasoline to contaminate the environment,” adds Norawit.

This “5G Zero Carbon Autonomous Roller for Salt Harvesting” prototype has been tested on campus, demonstrating its ability to perform driving, reversing, and forward movements like a regular vehicle, but without a driver. It can be monitored via a mobile phone.

This autonomous electric roller is one of its kind that is created to support salt harvesting, utilizing the robotics and automation technologies.